Bing 32mm carburetor restoration

The 1976 BMW R75/6 motorcycle uses a pair of Bing 32 mm carburetors. I decided to rebuild the ones on my motorcycle.

The exterior of the carbs were pretty dirty and there was also a fair amount of corrosion. This bike probably spent a decade or more in unsheltered storage. Inside the carbs I found three major problems: particulate and sludge contamination, dried out and cracked O-ring seals, and incorrect parts. The incorrect parts were the main jet, needle jet and the atomizer. These all have a major effect on fuel mixture from throttle positions of 25% to wide open. I also found a lot of corrosion and contamination on the idle screw needle valve. This effects the mixture from idle to 25% throttle position.

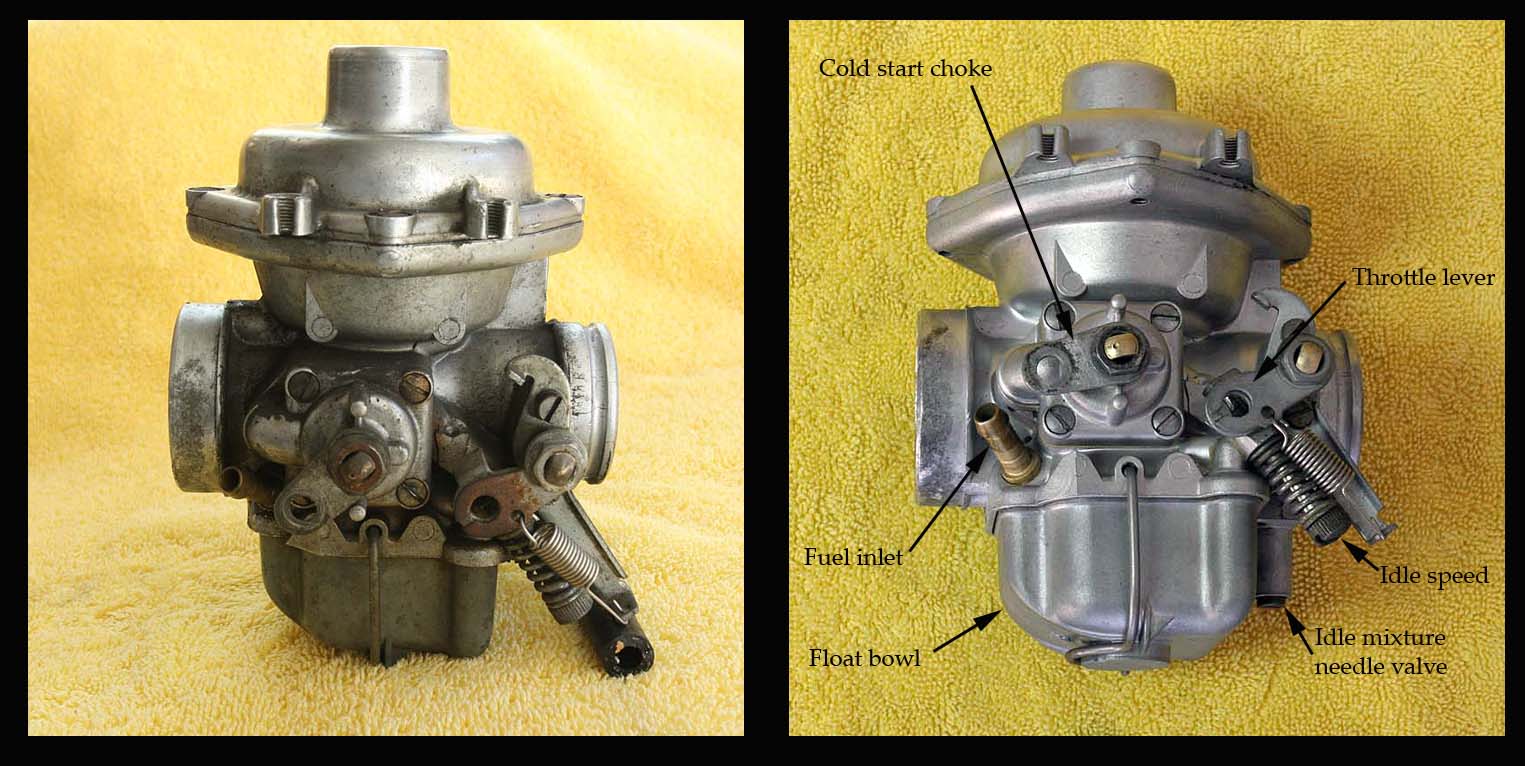

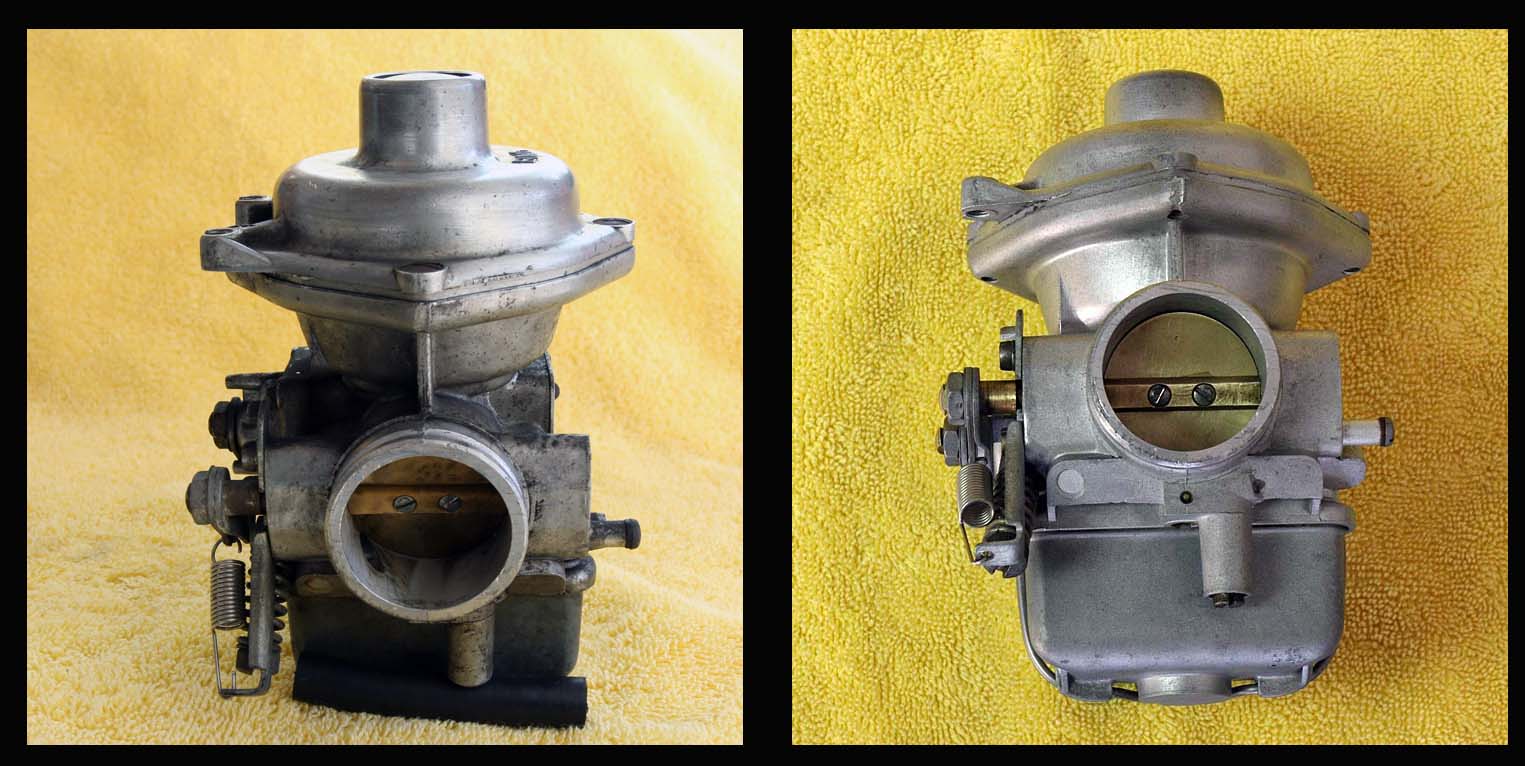

Here is a before-and-after comparison for the exterior of the carburetor.

There are a lot of parts in a carburetor, some of them quite small. And many of them are precision parts, like the piston slide tube.

An 18-egg family sized egg carton is ideal for keeping track of things

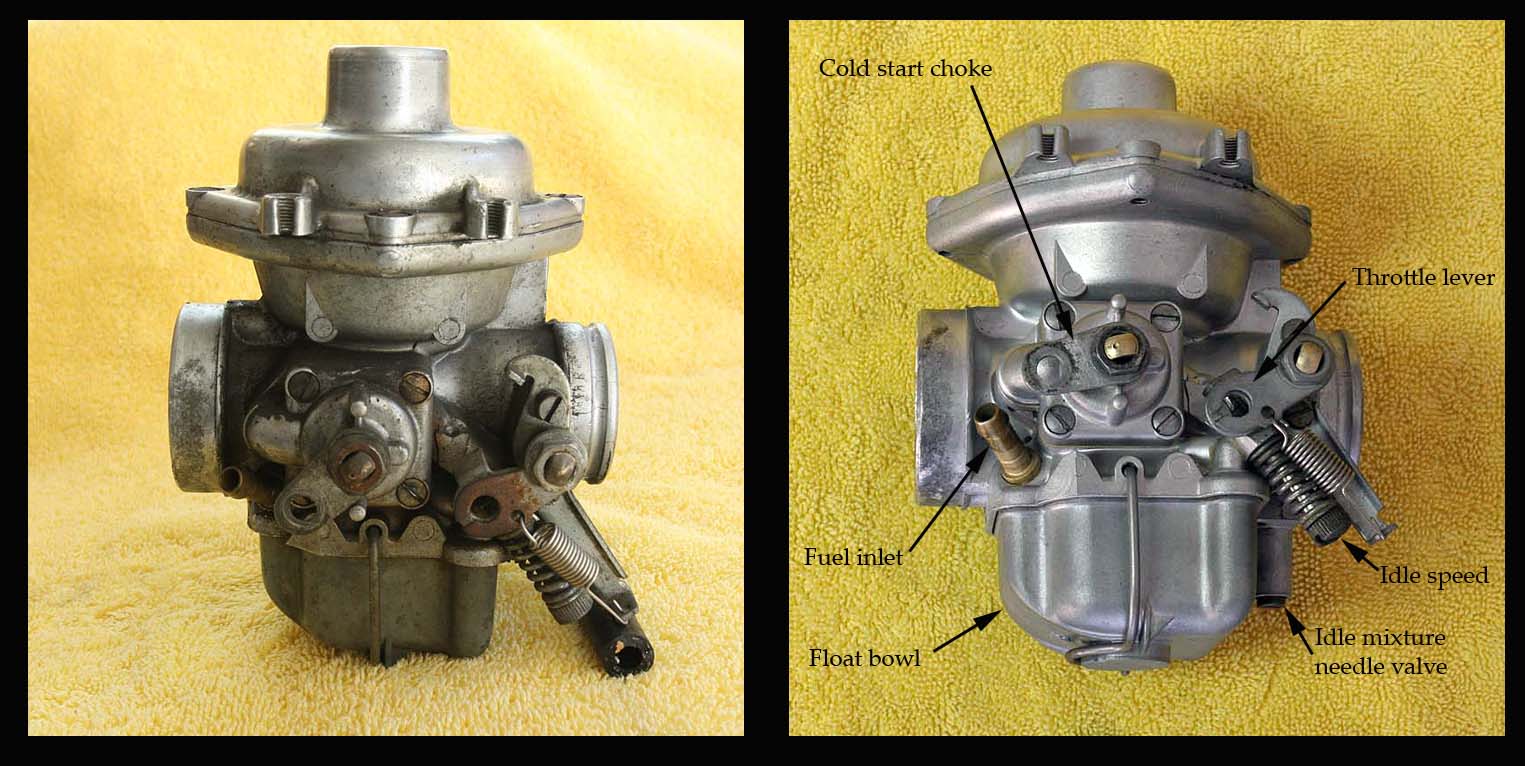

This is the idle mixture adjustment needle valve. It's amazing to me that it worked at all.

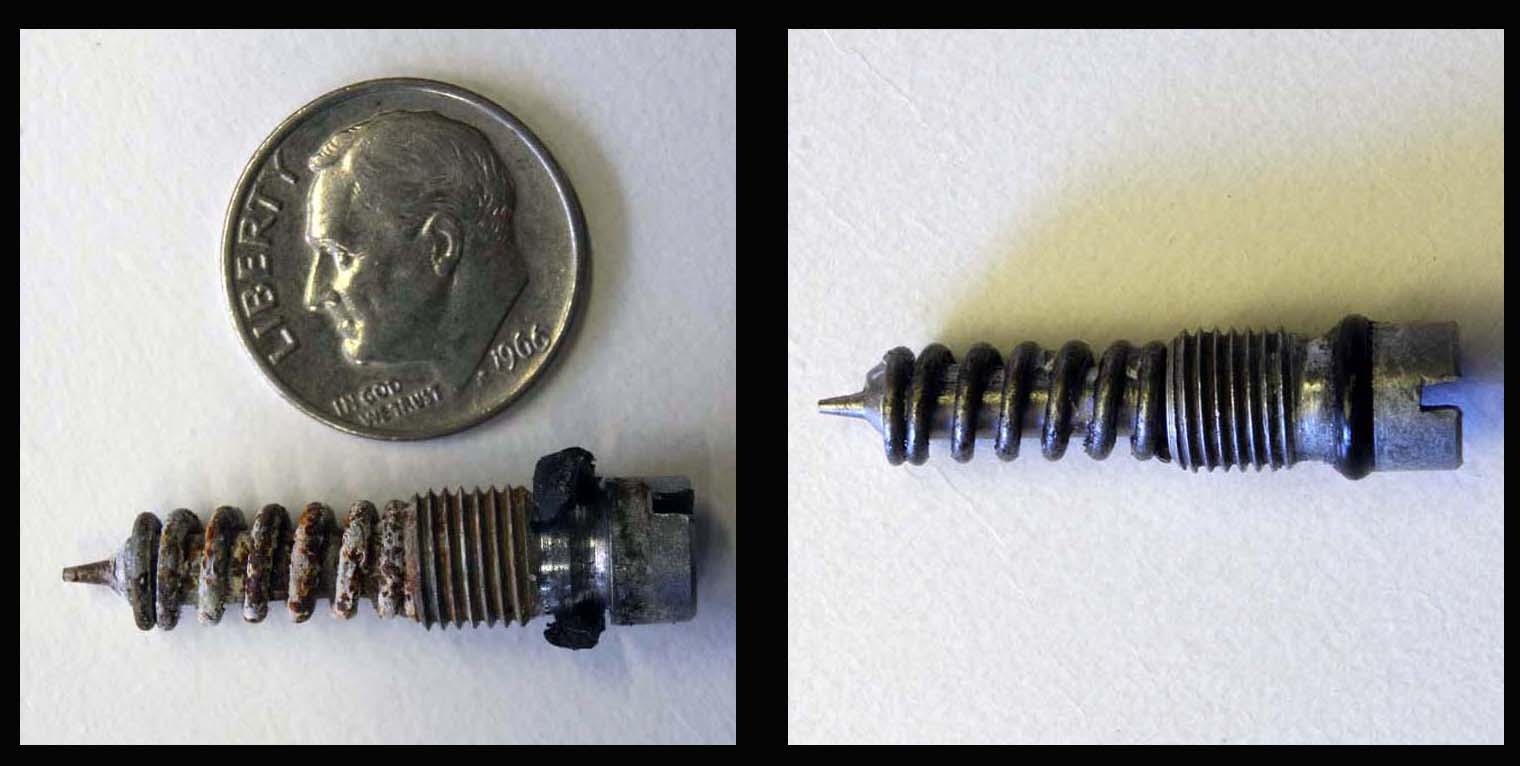

Here is the main jet venturi, needle jet and atomizer (left to right). Lots of staining and gunk. And, worst of all, the needle jet and atomizer (and main jet, not shown here) were different than what is specified by BMW for this motorcycle. I purchased and installed the correct replacement parts.

The mid-throttle needle, which slides up and down in the needle jet, adjusts the fuel aperture. The installed part shows signs of wear and corrosion, so I replaced them.

The floats were not defective, but they did show some signs of discoloration and swelling. They were replaced along with the float needle and the float shaft. This should assure a well controlled fuel level in the bowl and minimize any overflow when the bike is parked. I still turn off the fuel petcocks when I'm done riding though.

Before and after, viewed from the throttle plate side.

And the finished product. While I had my bead blasting equipment out I gave the cylinders and valve covers a shot too. The motorcycle started up and ran pretty well but needed the idle mixture, idle speed and carb synchronization adjusted. That only took a few minutes. Runs great now.